applications of brinell hardness test|brinell hardness testing machine diagram : manufacturing The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested . WEB4 dias atrás · 20/02/2024. Dezenas sorteadas 09 28 33 43 45 55. Prêmio estimado para o próximo concurso 2691 a ser realizado em 22/02/2024. R$ 97.000.000,00. Premiação. Faixa de Premiação. Nº de ganhadores. Valor do Prêmio (R$) Sena.

{plog:ftitle_list}

web16 de set. de 2023 · Game menu Back to game. Achievements. Statistics

What are the Applications of the Brinell Method? The Brinell hardness test is used to measure and inspect materials with rough surfaces such as forgings and casting .The Brinell Hardness Test is performed in a Brinell Hardness Test Unit. In this test method, a predetermined force (F) is applied to a tungsten carbide ball of fixed diameter (D), held for a .The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .

The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to . ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for .Applications of Brinell Hardness Test. The Brinell hardness test is used in various industries, including automotive, aerospace, and construction. It is commonly used to determine the hardness of metals, including steel, .Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information .

Selecting the Best Hardness Testing Method for Your Application. The following table provides an overview of various materials, including metals, along with the corresponding hardness testing methods applicable to each. . Brinell Hardness Test. The Brinell hardness test is ideal for measuring the hardness of metals with coarse or .The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material or material treatment is suitable for the purpose you require. . The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a . According to me, there are three basic types of hardness testing machines used in many applications which include; Rockwell, Brinell and Vickers. Rockwell Hardness Machine: It is known for its speed and simplicity of operation .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

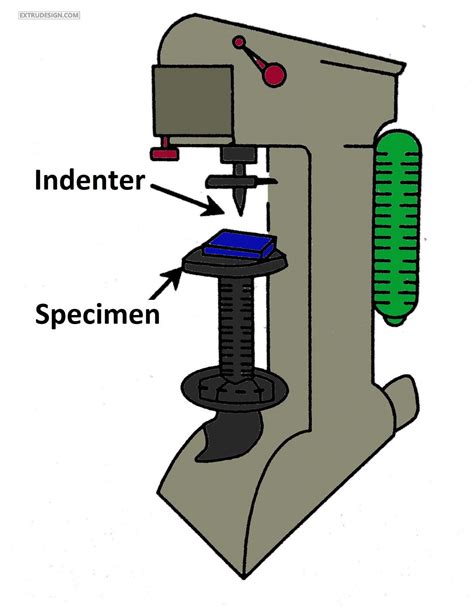

Andrew Fee, Selection and Industrial Applications of Hardness Tests, Mechanical Testing and Evaluation, Vol 8, ASM Handbook, Edited By Howard Kuhn, Dana Medlin, ASM International, 2000, . Brinell hardness test. Rockwell hardness test. Vickers hardness test. Knoop hardness test. surface condition. hardness. accuracy. calibration. case depth . General Information about the Brinell Hardness Test. The Brinell hardness test involves pressing a hard ball indenter, usually made of tungsten carbide, into the material’s surface with a specified force. The diameter of the ball is typically 10 mm, but smaller diameters such as 2.5 mm can also be used for specific applications.

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Characteristics and Application of Brinell Hardness. This method is well-suited for coarse or heterogeneous materials due to its large indentation area and high measurement accuracy. However, due to the large .SCOPE. The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or . tensile strength, yield strength, and ductility, contributing to the manufacturing success. With an immense range of applications, hardness testing forms the backbone of several industries such as automotive, aerospace, and .

Brinell hardness testing methods are defined in the following standards: ASTM E10 and ISO 6506. . Lower forces and smaller diameter balls are also used in specific applications. Similar to Knoop and Vickers testing, the Brinell test applies only a single test force. After removal of the load, the resultant recovered round impression is .Application of Brinell Hardness Test in Various Industries. The Brinell Hardness Test finds extensive application across diverse industries, playing a crucial role in assessing material hardness and ensuring the quality and reliability of products. Below are some key industries where the Brinell Hardness Test is commonly employed. 1. ManufacturingDirect Measurement: In certain applications, the material’s hardness stands as a crucial and directly measurable characteristic, eliminating the need for inference from physical properties. . Brinell Hardness Test: Using a spherical indenter, this test determines the hardness by measuring the diameter of the indentation created by a known .

Hardness testing is of immense importance for quality assurance in industry. Although the most widely used hardness test methods for metals—Rockwell, Brinell, and Vickers—were developed between 1900 and .

The Right Hardness Testing Method for Your Metals Application The right hardness test method depends on the material being tested and the specific requirements of the application. Understanding the differences .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. Capabilities. Processes. Heat Treating. Annealing; . The downward distance the indenter traveled from the application of the light load to the release of the heavy load is recorded and used to calculate hardness.

Note: for a general overview of hardness testing – concept, origins, developments and current methods, see our article here.. The need to understand the hardness of metal for various applications dates back to antiquity (in numerous engineering situations (and this includes hand-tool engineering) having the wrong hardness could cause catastrophic .The hardness of metals can be tested by 12 different hardness tests and the Brinell Hardness test is the oldest technique to measure the hardness of metals but is widely used. In this blog, we will discuss only Brinell Hardness test methods, including principle and theory, applications, advantages and disadvantages. Among the various hardness testing methods, the Brinell and Rockwell tests are two of the most commonly used techniques. In this article, we will compare these two methods, highlighting their differences and applications. Brinell Hardness Test. The Brinell hardness test is named after its inventor, Johan August Brinell. It measures the hardness .

Gas Permeability Test System consultant

Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it. Hardness, as defined in the first chapter, is a type of resistance to deformation, the roots of which lie in the packing density of atoms and the bonding forces that keep them in place.For metric applications the tensile strength in N/mm 2 can be obtained by multiplying the Brinell number by 3.54 for annealed steels, . In the Brinell test, hardness is defined as load divided by the curved area of the indentation; in the Vickers test, the diagonal of the square impression is measured. The Vickers test was in due course . Benefits and applications. The benefits of the Brinell hardness tester are wide-ranging, with practical uses across industries. . the part of a Brinell hardness testing device that presses into the material being tested, forming an indentation. Typically, the indenter is a hardened steel ball, but a tungsten carbide ball can be used when .

The Brinell hardness test consists of applying a constant load or force, usually between 187.5 and 3000Kgf, for a specified time (from 10 – 30 seconds) typically using a 2.5 or 10mm diameter tungsten carbide ball (see schematic in the image to your right – Figure 23.3). . Applications. Brinell hardness testing is typically used in testing .Brinell hardness test has wide applications in the metal forging and manufacturing circles, where it is used for ascertaining the tensile strength of metals. Since the range of applied force ranges from low to high, the Brinell hardness test can be applied to metals like copper and aluminum using low forces and cast irons and steel with higher .

brinell hardness testing procedure

brinell hardness testing method

Se Malphite non viene colpito per qualche secondo, questo effetto si ricarica. Q Scheggia sismica. Malphite scaglia un frammento di terra attraverso il suolo fino al suo nemico, infliggendo danni all'impatto e rubando velocità di movimento per 3 secondi. W Ruggito del tuono. Malphite attacca con forza tale da creare un boato sonico.

applications of brinell hardness test|brinell hardness testing machine diagram